The Lust for Leather

“The most effective way to distort reality is to deny it …And the most effective way to deny a reality is to make it invisible.”

– Melanie Joy

As a material, leather is hard to beat. It is strong, durable, and fashionable. Long considered a luxurious material, it has a timeless aesthetic that is highly versatile in its applications. Available in varied colors and textures, leather is used to make a panoply of goods including clothing, footwear, handbags, furniture, tools, and sports equipment. It is breathable, water-resistant, and able to withstand harsh weather conditions. The strength of leather lies in its fibers, long tight strings made of collagen, like a million knotted fishing lines weaved into a single sheet. As leather ages, it becomes more soft and supple, revealing subtle changes in appearance. This ‘patina’ gives leather a uniquely warm, lived-in look. Premium, high-quality leather can last for generations.

A Material for the Ages

Humanity’s love affair with leather started thousands of years ago. Leathermaking dates back 7,000 years when it was used for shelter, clothing, and footwear. Initially preserved by salting and smoking, the process of vegetable tanning was developed by the Egyptians and Hebrews around 400 BC.1 Through the Middle Ages (500-1500 A.D.) and the Renaissance (1450-1650 A.D.), leather saw increased popularity. In addition to tanning, leather was carved, dyed, molded, painted, shaped, and stamped. These techniques were honed during the Enlightenment (1685-1815 A.D.) when leather was utilized for book covers, shoes, hats, bags, furniture, and more.2 Chromium tanning replaced vegetable tanning in the mid-1800s, as it is faster and creates leather that is more supple and pliable. Its functional properties are myriad:

The global leather market was valued at $444 billion in 2023, growing at a 5.8% CAGR, and is expected to reach $735 billion by 2032.3 It dwarfs in size markets for other materials such as polyester ($81 billion), cotton ($39 billion), wool ($38 billion), silk ($34 billion), nylon ($31 billion) and denim ($19 billion). China is by far the largest leather producer in the world, followed by Brazil, Russia, India, and Italy. North America is the largest market for leather goods, accounting for 37% of the market, while Asia-Pacific will see the fastest growth over the next decade. Footwear is the largest product segment, followed by apparel, automotive, and handbags. Because it is seen as a luxury product, rising global affluence is fuelling increased demand for leather. According to a 2022 survey in the United Kingdom, 67% of consumers say they buy and use leather because they can trust it to last a lifetime, while 55% say it's a high-quality material.4

The Making of Leather

Today, 65% of leather in the U.S. is made from cattle and calf skins, but leather is also made from sheep (13%), goats (11%), and pigs (10%).5 However, leather can come from any land animal as well as aquatic animals. Species hunted and killed specifically for their skins include alligators, bison, crocodiles, elephants, kangaroos, lizards, ostriches, snakes, and zebras. The hides of cows raised and slaughtered for meat are then diverted toward leather production. The hides of their calves, frequently raised for veal, are made into high-priced calfskin. Sidestreams of meat, of which leather is a key component, can account for up to 26% of the big slaughterhouses’ earnings.6 As a result, the economic success of slaughterhouses and dairy farms is directly linked to the sale of leather goods.

Once the hide is obtained, the leather production process today consists of three steps:

Preparation: May include soaking, hair removal, liming, deliming, bating, bleaching, and pickling

Tanning: Stabilizing collagen to increase the thermal, chemical, and microbiological stability of the hides and skins by using agents such as chromium salts, vegetable extracts, or other chemicals

Crusting: Neutralization of the residual acids from the tanning process, followed by splitting, dyeing, fatliquoring, drying, and conditioning

A Finishing process can be added, which may include oiling, brushing, buffing, coating, polishing, embossing, glazing, or tumbling.

The Cost of Leather

The leather tanning process, essential to creating a long-lasting product, involves soaking animal skin in a cocktail of chemicals to permanently alter the protein structure of the skin, preventing it from breaking down. A common misconception is that leather is natural, biodegradable, or eco-friendly. Ironically, the tanning process stops the leather from biodegrading by stabilizing the collagen or protein fibers, turning a natural material into an unnatural one. Approximately 90% of tanneries use chromium,7 which produces the toxic chemical by-product hexavalent chromium, a known human carcinogen. Other chemicals used in the process include cadmium, chlorine, formaldehyde, lead, nickel, and zinc. For its allure and benefits, leather extracts a heavy toll from animals, people, and the planet.

Animals

FAO estimates that 2.29+ billion animals were killed to make leather worldwide in 2018.8 At slaughterhouses, animals are often skinned and dismembered while still alive. A PETA short video, Hell for Leather, which exposes these practices, is disturbing to watch. While 84% of brands source leather for their fashion supply chains, just 26% of them have a stated animal welfare policy or statement.9 Almost half the leather trade is carried on in developing countries, where there is little oversight or attention to animal welfare. While understanding the species and origin of leather can provide valuable insights into the ethical treatment of animals, environmental impact, and the overall transparency of the production process, leather products may be deliberately mislabelled when it comes to both the country of origin and even the species. Short of a DNA test, there is little consumers can do to determine whose skin they are wearing. To obfuscate the process further, if an animal was skinned in China, after which skin was imported by Italy to manufacture the final product, the label will simply state it was ‘Made in Italy’. This can mislead consumers and mask illegal activity.

People

Because leather production is so unsafe, it is moving out of developed countries into developing ones, where regulations are lax, labor is cheap, and tragically, loss of health or life escapes scrutiny. An investigation into the industry in Dhaka, Bangladesh found 15,000 laborers – some as young as 10 – toil in more than 150 tanneries.10 Workers stand barefoot in wastewater with toxic chromium and handle acids and bleaches that can cause chronic skin diseases and even cancer while being exposed to fumes that can damage vision and cause severe respiratory problems without the benefit of protective goggles. Some workers lose fingers to the conveyor belts. According to the WHO, 90% of tannery workers in the region die before the age of 50.11 Those in surrounding communities to tanneries face a range of health issues, including increased cancer rates, leading to what has been termed “cancer villages”. The U.S. Centers for Disease Control and Prevention (CDC) found that the probability of developing leukemia for those living near a tannery in the U.S. state of Kentucky was five times the national average. Tannery workers in Italy and Sweden are 20% to 50% more likely to have cancer.12 Even consumers are not spared. Studies have demonstrated that finished leather products that directly touch the skin can contain high levels of chromium, which may cause skin reactions such as eczema. A German study found chromium in over half of the leather products it inspected.13

Planet

Tanneries pollute land, water, and air. Every year, over 4 million tonnes of solid waste is generated by the global leather industry.14 Producing leather is wasteful – 500kg of rawhide only produces 75kg of leather. The remainder is waste, releasing methane gas into the atmosphere as it breaks down. Processing one ton of hide requires 60,000 liters of water.15 That’s nearly 8,000 gallons of water to produce a single leather jacket.16 The toxic chemicals used to tan leather are then dumped into waterways, particularly in developing countries that have limited environmental protection. This not only kills fish and other water life, but also poisons those that drink the water including both land animals and humans. Leather’s impact extends to deforestation, as the cattle industry is the biggest culprit behind the destruction of the Amazon, a majority of which is done illegally. Pure Earth, which identifies and implements solutions that stop toxic exposures, concluded that tanneries are one of the world’s top 10 toxic industries.17

The Evolution of Leather

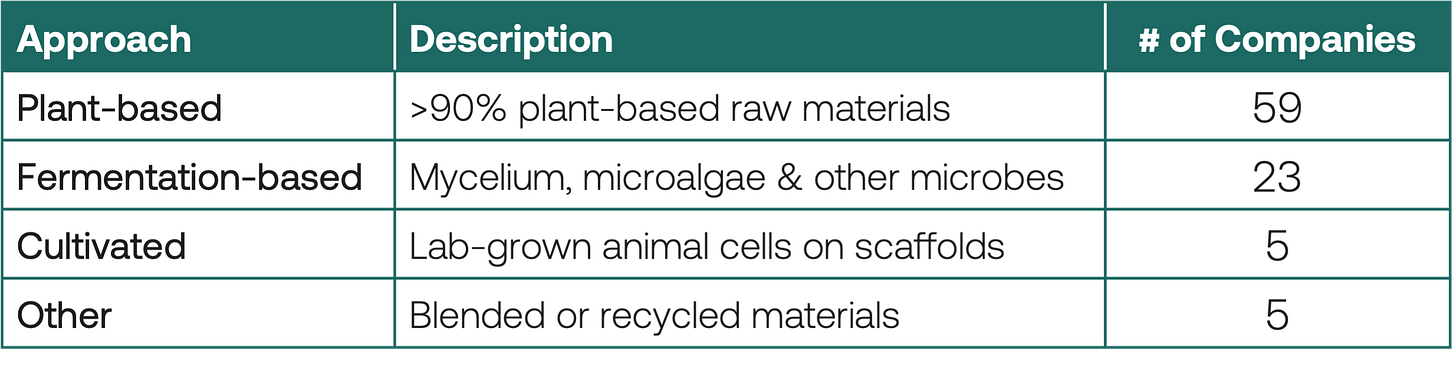

Sometimes, it is necessary to take a step backward to take two steps forward. The alternative leather industry, which seeks to find animal-free substitutes to leather, appears to face this conundrum. According to the Materials Innovation Institute (MII), 92 companies are focused on creating leather free of animals using a variety of approaches:

Alternative leather faces major challenges. Taking any material and using it to replicate another requires both biological and chemical acrobatics that are cumbersome and costly. This raises the price of the end product. Conventional leather is strong, long-lasting, and luxurious, and offers a range of finished product formulations. A substitute using other materials may replicate some of these attributes, but will invariably fall short of matching leather holistically. To compensate, some companies blend polyurethane (PU) and polyvinyl chloride (PVC), which are derived from fossil fuels. This runs counter to sustainability goals due to both the source and lack of biodegradability. While cultivated technology can potentially create a bioidentical product, there has been surprisingly scant innovation and funding for this technology compared to meat substitutes.

This is not to discount the incredible strides made in recent years. In the past decade, over $3 billion has been invested in next-generation materials companies, more than half of it since 2021. Still, crossing the price-performance barrier to match leather’s durability, texture and appearance has so far been beyond reach. To accelerate the adoption of alternative leather, the industry must address significant challenges, which include:

Durability: Vegan leather lasts 2-5 years, whereas conventional leather lasts decades. During its life, leather does not dry out, peel, crack, or crease upon bending. There is no change of color due to exposure to extreme light, heat, or ultraviolet rays from sunlight, nor is there damage from water. These properties are difficult to achieve without the use of hydrocarbons (oil-based additives).

Appearance: Alternative leather producers are targeting luxury fashion brands due to higher prices and margins. It should be noted, then, that luxury hides tend to have exotic colors and patterns along with exceptional long-term durability, raising the bar for immaculate appearance and exceptional quality required of alternative leather.

Texture: Animal leather can feel coarse or smooth depending on its type and quality. The surface also has a natural grain along with a distinctive leather smell. Real leather is less consistent in texture, which lends it character in the eyes of consumers. It is also elastic – press your fingertip against natural leather and wrinkles form, after which the material returns to its original state.

Cost: Conventional leather costs $3-10/sq ft for non-luxury hides and $10-25/sq ft for luxury hides.18 Bolt Threads, a leading company in the alternative material sector, says its fabric costs about $25/sq ft19, which according to the company, puts it on par with premium calf leather.

Versatility: Leather is used to make a range of products including shoes, handbags, clothing, furniture, and automotive interiors. For example, shoes require a thicker, sturdier material while car seats are made from a more flexible and smoother version. Alternative leather must be able to adapt to these requirements.

Sustainability: Alternative leather has an opportunity to shine here. A Life Cycle Assessment (LCA) conducted by Modern Meadow has shown that alternative leather utilizes 50% less energy and leads to 80% lower GHG emissions compared to conventional leather. It also reduces eutrophication potential, land use, and water consumption by over 95%. However, to match price and performance, the use of PU and PVC plastics can degrade these marks and cast products in a negative light with consumers. Cultivated technology also typically utilizes significantly more energy than other approaches to alternative leather.

For The Love of Leather

While animals pay the ultimate price for leather, its impact is toxic to both people and the planet. For luxury brands, leather is a cash cow. It is not so much a ‘by-product’ of the meat industry as a ‘co-product’, enabling animal agriculture to drive higher margins and increase profits. Leather is loaded with toxic chemicals; otherwise, it would degrade in the closet or the car seat. Perhaps Stella McCartney puts it best – “An animal decomposes when it’s natural, but after all of the chemical treatments [applied] to a leather handbag, it isn’t going to decompose in your wardrobe. That product is staying alive because of the chemicals that have been put on it—because if you just had a dead animal in your closet, it would be a very different situation.”20

The demand for both food and skin from animals continues to rise. Yet, technology has the power to create better solutions and deliver more than consumers expect. Think back to mobile technology before the iPhone, for example. Innovation is happening all around us today – just ask Google about the launch of OpenAI’s ChatGPT. Today, there is no serious challenger to leather at scale that meets all the requirements for mass adoption. To get there will require more funding and innovation. The opportunity is enormous, and so is the urgency.

Britannica Encyclopedia, Leather

ABI Tape, Leathercraft

Precedence Research

Leather UK

Wikipedia

Bain and Company

U.S. Environmental Protection Agency

Institute of Animal Law of Asia

Four Paws Australia

Human Rights Watch

The Guardian

Earth.Org

German Federal Institute of Risk Assessment

Ali, et al. (2023), A renewable and sustainable framework for clean fuel towards circular economy for solid waste generation in leather tanneries

Karuppiah, et al. (2020), Leather waste management scenario in developed and developing nations

Los Angeles Times

Pure Earth Organisation

Liberty Leather

Bloomberg

Vogue

Great analysis! I'm bullish on fermentation-based solutions for leather 🙌🏾