'Casein' Point: How Science is Reshaping Cheese

“Tradition is not the worship of ashes, but the preservation of fire.”

– Gustav Mahler, Composer

Deeply rooted traditions and cultural practices shape individuals and communities. People find comfort in familiar foods passed down through generations, seeing them as essential to their heritage and family connections. Cultural norms dictate not only what is eaten but also how food is prepared and shared, making dietary shifts challenging. As a result, the global food system has been slow to change for decades, if not centuries. Although technological advancements, such as improved efficiency and yield, have emerged, the basic approach to growing crops and raising livestock largely persists. Cheese production is similar, where local cheese varieties are seen as integral to respective culinary identities globally.

Cheese-making dates back thousands of years, making it one of the oldest human-made foods. While the exact origin of cheese is unclear, it was likely a result of an accidental discovery, possibly occurring when milk stored in containers made from animal stomachs (which contain rennet, an enzyme that triggers coagulation) separated the milk into solid curds and liquid whey.1

Aged to Perfection

The first evidence of cheesemaking comes from pottery fragments in what is now Poland, dating back to 5500 BCE, which show signs of milk fat.2 Early cheese was made by curdling milk with natural bacteria or rennet, separating curd (solid) from whey (liquid). This process allowed milk to be preserved for longer periods, which was crucial for ancient civilizations. Archaeological evidence from ancient Egypt, including tomb paintings, shows cheesemaking as a common practice.3 Clay tablets found in Mesopotamia mention 20 varieties of cheese.4 In ancient Greece, cheese was a highly valued food. Homer mentioned ‘tyros’,5 the Greek word for cheese, in The Odyssey, where Cyclops (a mythical one-eyed giant) is described as making cheese from sheep's milk.

The Romans developed more sophisticated cheesemaking techniques, creating aged and diverse varieties of cheese. They introduced cheese to conquered lands, spreading the practice throughout Europe.6 Cheesemaking continued to develop through the Middle Ages and the Renaissance, with increased trade, exploration, and advancements in agricultural techniques. European settlers brought cheesemaking to the Americas, but cheese did not become widely popular in the United States until the 19th century. The first cheese factory in the U.S. was established in New York in 1851,7 producing Cheddar, which became the dominant type of cheese in the country. The introduction of mechanised equipment in the 19th century enabled large-scale cheese production.8 As cheese factories appeared, the process became more standardized and efficient. The mid-20th century saw a resurgence of interest in traditional, small-batch cheeses, particularly in Europe and North America. The farm-to-table movement and growing consumer interest in quality, heritage, and craftsmanship have led to the rise of specialty cheese markets.

Image Credit: Designed by FreePik

Curdling Transformation

The word cheese comes from Latin caseus, from which the modern word casein is also derived.9 Cheese is produced from the curdled milk of cows, goats, sheep, or other mammals. Over a thousand types of cheese exist across the globe. Cheese can be classified based on various criteria, such as milk source, flavour profiles, geographical origin, fat content, production method, texture, and the aging process. Among these, the latter two classifications (described below) are most commonly used:

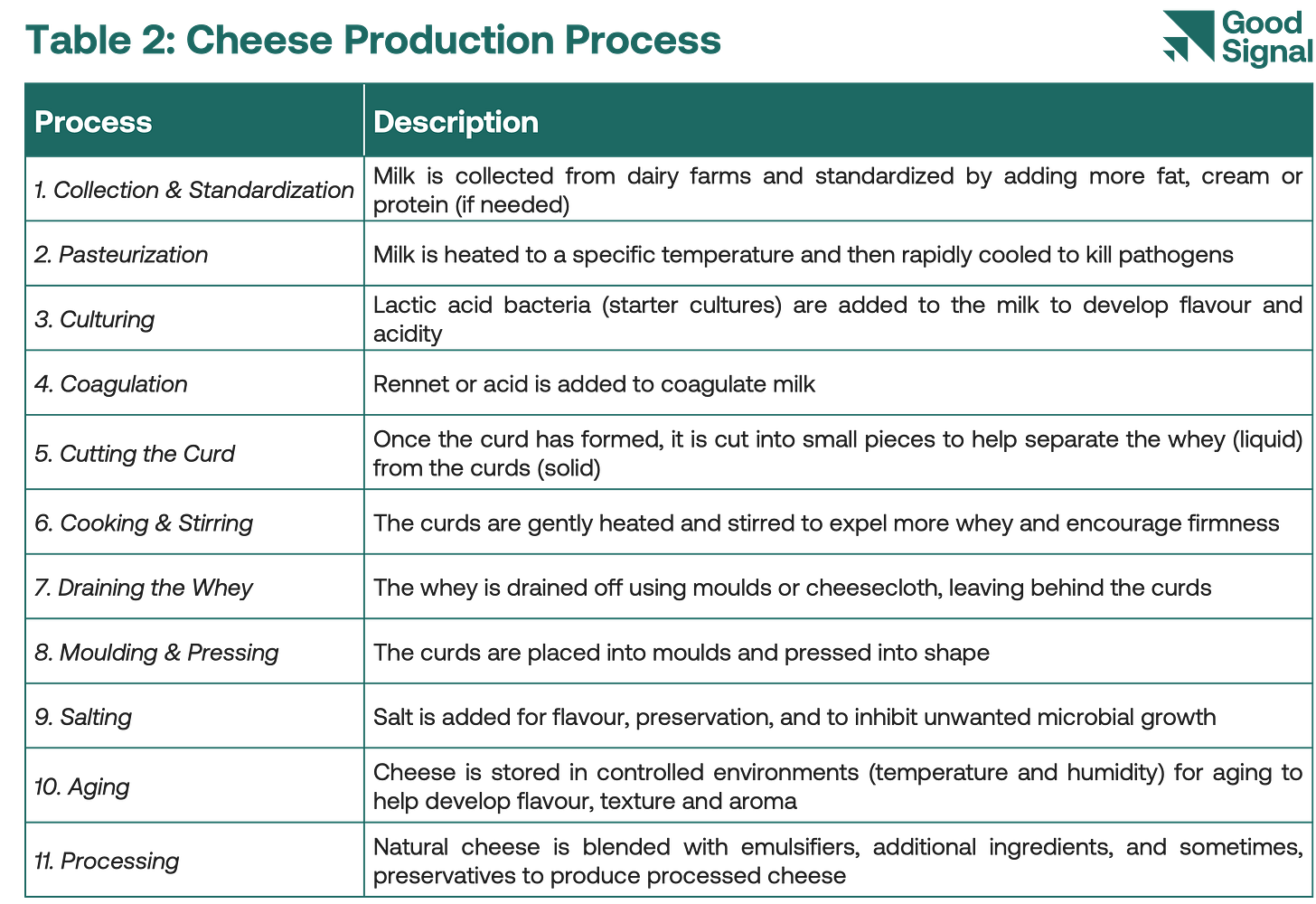

The style, texture, and flavour of the cheese depend on various parameters such as the origin of the milk (including the animal's diet), whether it has been pasteurised, the protein-to-fat ratio, the bacteria and mould, the processing, and how long it has been aged. These parameters can be fine-tuned during the production process (described below). Some steps can vary depending on the type of cheese being produced.

Each step from milk collection to aging plays a vital role in developing the cheese's unique characteristics, including its texture, flavour, and aroma, though culturing and coagulation are the foundational steps in the cheese-making process.

Culturing: Culturing refers to the process of adding specific strains of bacteria, known as starter cultures, to milk before the coagulation phase. The bacteria ferment lactose, the sugar in milk, into lactic acid. This lowers the pH of milk, creating an acidic environment that is essential for curd formation. Different bacterial strains also impart unique flavours, aromas, and textures to the cheese.

Coagulation: Coagulation is the process of transforming liquid milk into solid curds through the addition of rennet or acids, such as lemon juice or vinegar. The use of acids is more common in the production of fresh cheeses like ricotta and cottage cheese. The texture and firmness of the curds depend on the coagulation method, the duration of the process, and the specific cultures used. During coagulation, casein protein, which comprises about 80% of the protein in cow’s milk, forms the curds, while whey protein, accounting for the remaining 20%, separates out into the residual liquid.

Not So Gouda

Owing to ongoing process improvements and innovation, global cheese production reached 22 million metric tons in 2023. The European Union was by far the top producer of cheese worldwide, with a production volume of 10.4 million metric tons or ~47% of global production.10 In dollar terms, the market was estimated at US$ 195 billion in 2023. Cheddar accounted for the highest share at 36.5%.11 Cheese production is growing with negative implications for animals, people, and the planet.

Animals: Many dairy operations use intensive farming methods that prioritize high milk production. This can lead to overcrowded conditions, limited space, and psychological stress for the animals due to the inability to form natural herd dynamics. Often, calves are separated from their mothers shortly after birth to maximize milk production for cheese. This separation can cause distress for both the mother and the calf. Dairy cows are also often culled when their milk production declines.

Additionally, rennet used in cheese production was traditionally derived from the stomach lining of young cows, sheep, and goats. The use of conventional rennet in cheese production has declined in recent years because of the increasing use of microbial rennet and plant-based enzymes. As per recent estimates, approximately 5% of rennet used in cheese production in the U.S. is animal-derived.12

People: Although cheese is a rich source of protein, calcium, vitamins, and minerals that support bone health, it is often high in saturated fat, sodium, and caloric density, which can be a contributor to chronic diseases. Further, processed cheeses contain artificial additives, preservatives, and emulsifiers which also have negative health effects. The use of dairy also poses a risk for 68% of the global population that is lactose intolerant to some degree,13 a figure that exceeds 90% in regions like East Asia.14

Planet: The environmental impact of cheese production is significant due to greenhouse gas emissions from dairy cattle, land use for dairy farming contributing to deforestation and biodiversity loss, and the use of significant water resources both during animal rearing and cheese processing. The energy-intensive nature of cheese production, from farming to processing and transportation, further compounds its ecological footprint.

Say (Alt) Cheese!

Alternative cheese offers the advantage of a lower carbon, land, and water footprint and promotes animal welfare by eliminating the need for dairy farming. It is also suitable for those with dietary restrictions. Alternative cheese can be made from a variety of plant-based, microbial, or cell-based sources. Caseins play a unique role in creating conventional cheese-like textures in alternatives since they are responsible for the structure, stretch, and meltability of traditional dairy cheese. As a result, they have been the focus of innovative developments in alternative cheese:

Plant-based cheese: Typically made from nuts (almonds, cashews), seeds (sunflower, pumpkin), legumes (soy), or starches (potatoes, tapioca), it doesn’t contain casein but it relies on fats, starches, and gums to replicate the taste and texture of conventional cheese. However, replicating the functions of casein, especially in terms of melting and stretchiness, has proven to be challenging using this approach given the lack of proteins.

Fermentation-derived cheese: Precision fermentation is often used to express bioidentical casein proteins from yeast or other microbes which are then formulated into cheese products. These caseins mimic the functional qualities of animal-based caseins, allowing for alternative cheese that melts, stretches, and has a firmer texture.

Plant-molecular farming (PMF)-derived cheese: Involves the use of plants as bio-factories to produce dairy proteins. Plants such as soybeans, beans, spinach, or even tobacco are genetically engineered to express specific dairy proteins, which are then harvested and used in alternative cheese production. PMF holds the promise of replicating the texture, flavour, and functionality of conventional cheese while embracing more eco-friendly production methods.

Cheese from cultivated milk: Bioidentical milk is produced using cow cells in this approach. This cultivated milk can then undergo the same cheesemaking process as conventional milk.

Hybrid cheese: Combines plant-based ingredients with fermentation- or PMF-derived caseins to get the best of both worlds – offering the sustainability and lower cost of plant-based ingredients combined with the functional properties of casein proteins.

Culturing the Micelle

Micelle formation can significantly enhance the quality of alternative cheese by improving the texture, mouthfeel and meltability. Let’s understand the micellization process a little better. Caseins – a group of closely related intrinsically disordered proteins (IDPs) – are central to the micellization process.15 There are four different types of caseins - αS1, αS2, β and κ-casein. When rennet or acid is added to milk, the pH drops, causing casein molecules to bond together and form larger structures called micelles. The casein proteins held together by calcium phosphate, which stabilizes the micelle structure. The micelle consists of a hydrophobic (water repelling) core and a hydrophilic (water attracting) shell. The core is mainly composed of α-casein (αS1 and αS2), which is hydrophobic, while the shell is made up of κ-casein, which is hydrophilic. β Casein is distributed throughout the micelle, contributing to its stability and structure. The size and stability of these micelles influence the texture and properties of the final cheese product. However, the structure of a casein micelle is sensitive to changes in environmental factors (pH, temperature, ionic strength), which can alter its functional properties.

While micelle formation is often considered the holy grail of cheese production, it remains a poorly understood process. Many startups are working to solve this challenge with varying degrees of success. It remains to be seen whether cost-effective micelle formation can be achieved at scale in the alternative cheese space.

Moo-ve Over Dairy

The shift toward alternative cheese represents a pivotal moment in food innovation, allowing us to preserve the rich traditions of cheesemaking while transforming the food system’s relationship with animals. While classic techniques and flavours remain valued, the transition to alternatives emphasizes a more sustainable approach to dairy production. This evolution redefines the role of animals in our food system, advocating for a kinder, more responsible future. So, we end with a tribute to the coming age of cheese:

From Europe to America and lands afar,

Cheese travelled the world, a culinary star.

Fresh, aged, soft and hard,

Crafted from milk and rennet, with lives left marred.

But times have changed, new winds now blow,

With plants and science, new flavours grow.

Innovating cheese in a kinder state,

A future unfolds, as we recreate.

International Dairy Foods Association

Subbaraman (2012), Art of cheese-making is 7,500 years old

National Historic Cheesemaking Center

History on the Net

Dalby (2003), Food in the ancient world from A to Z

International Dairy Foods Association

Johnson (2017), A 100-year review: Cheese production and quality

Powell et. al. (2011), Cheese | Starter Cultures: General Aspects

Naria Cheese

Statista

Grand View Research

The Vegetarian Resource Group

National Institute of Diabetes and Digestive and Kidney Diseases (United States)

National Library of Medicine (United States)

National Library of Medicine (United States)

Well written description of changing landscape for cheese and poetic to the end.